Many people already know the basics of spray drying and how it works, but there are several facets to this complex process. The primary objective of spray drying is to transform a liquid into a powder through quick drying with a hot gas. For many thermally sensitive items such as those in the pharmaceutical or food industries, this is one of the preferred methods of drying. Keep reading below to find out more about spray drying and its applications in industry:

A Basic History of Spray Drying

The development of spray drying technology and techniques evolved from the 1870s through the early 1900s. The first type of spray dryer used nozzle atomizers, but this type of technology was very slow and often unreliable. Not only that, but they were also difficult to use too. It wasn’t until several decades later that rotary atomizers were introduced. These atomizers are still used by contract spray drying companies today.

The Spray Drying Process

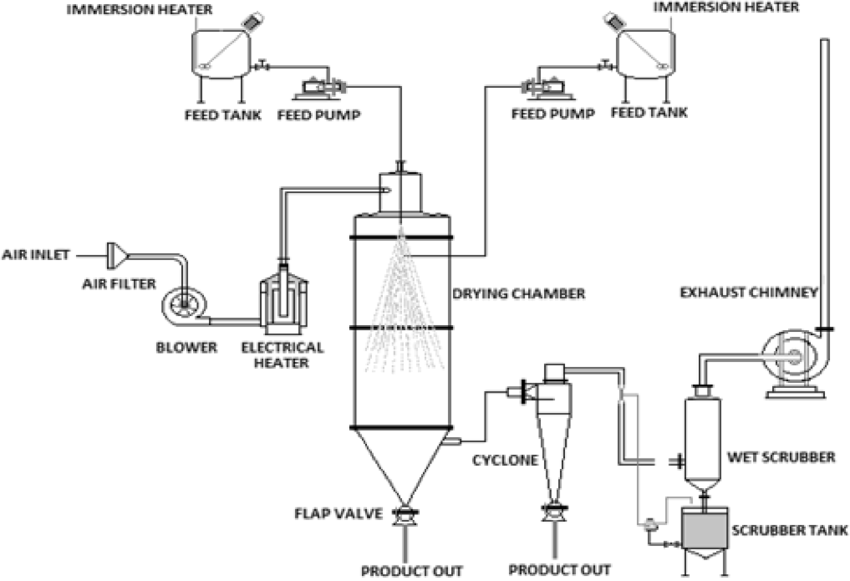

Spray dryers take a liquid and break up the solvent into a vapor and the solute as a solid. A cyclone or drum then collects the solid before a liquid input stream sprays in a heated vapor stream and vaporizes. As the moisture disappears, a solid is created.

Spray dryers require substantial amounts of hot air in order to work. The quality of the finished product can be affected by the amount and the quality of the air that enters the dryer. The air needs to be odorless, free of contaminants, and dry in order to produce the highest quality finished product.

The most common types of dryers are called single effect types. These dryers have a single source of drying air which is located at the top of the chamber. However, this type of dryer can have poor flow and it can also produce more dust than other methods. Thanks to this, new spray dryers have been introduced that, instead of drying the liquid in one step, dry it in two stages. The first stage is the same as the single effect dryer, at the top. However, the second is the use of a static bed at the bottom of the chamber. These dryers create more uniform particles.

Spray Drying Applications in Industry

Spray drying is now used by several different industries. However, the industries that utilize this method the most are pharmaceuticals and food processing. It is also used to create ceramic materials, paint pigments, catalyst supports, and for use with microalgae.

Spray drying is used a lot in pharmaceutical manufacturing. Spray drying pharmaceutical products helps to uniformly disperse active components into a polymer matrix. This helps to facilitate the diffusion of the drug in a patient’s body. The manufacturing of medicinal ingredients, additives, and antibiotics also uses spray drying technology.

Another industry that regularly uses spray drying technology is the food industry. Most manufacturers in the food industry choose to use the encapsulating method to prepare powders out of substances that do not contain any water. For example, several substances that make up a drink are spray-dried to create instant drink mixes. This process is also used to remove water from food items, such as coffee, tea, spices, powdered milk, and powdered eggs.

Spray drying technology has been around for many years now and has improved a lot since it was first introduced. It is now one of the preferred methods used by several industries including the food industry and the pharmaceutical industry.